Crane Collar Machine - Ø620-Ø1200

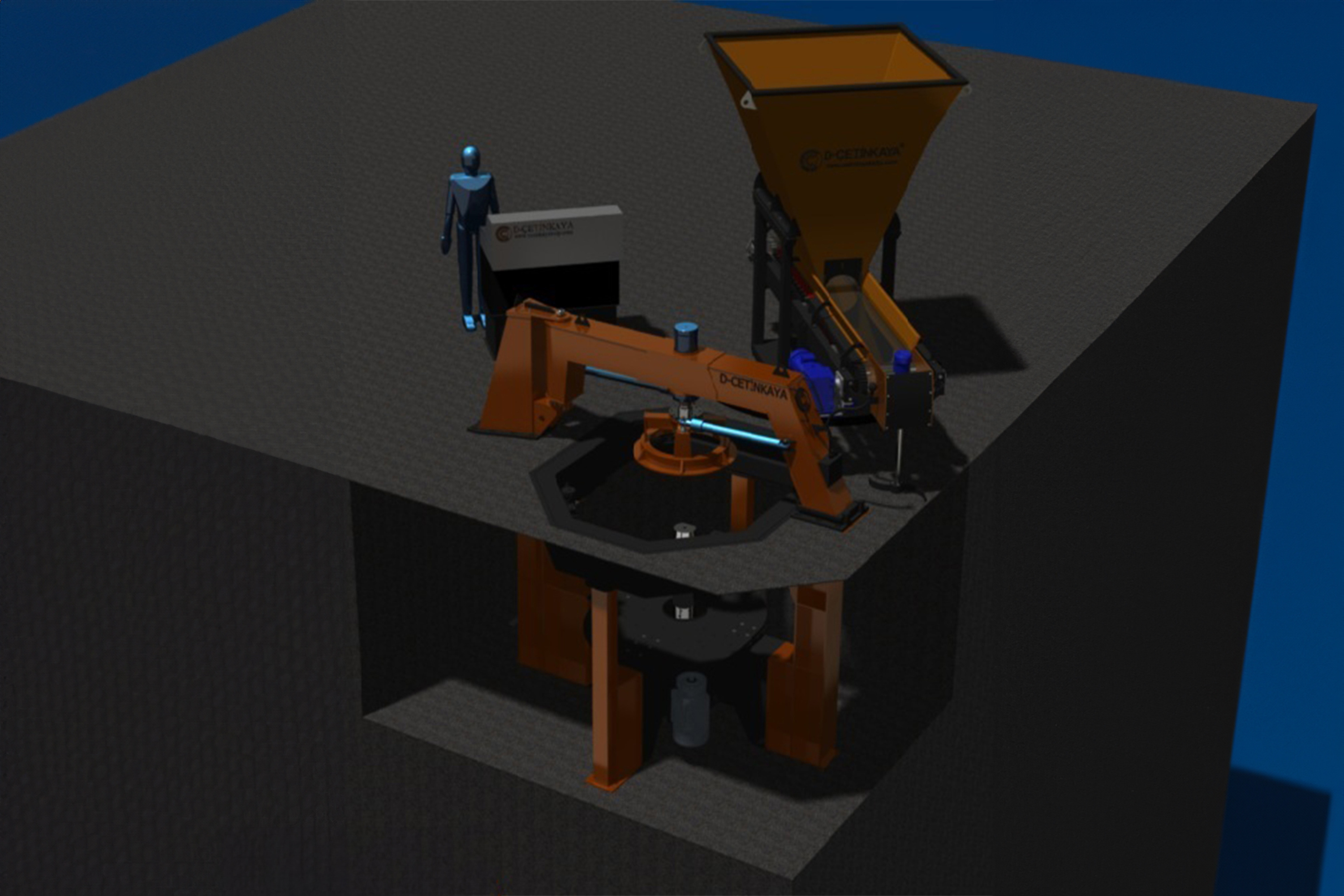

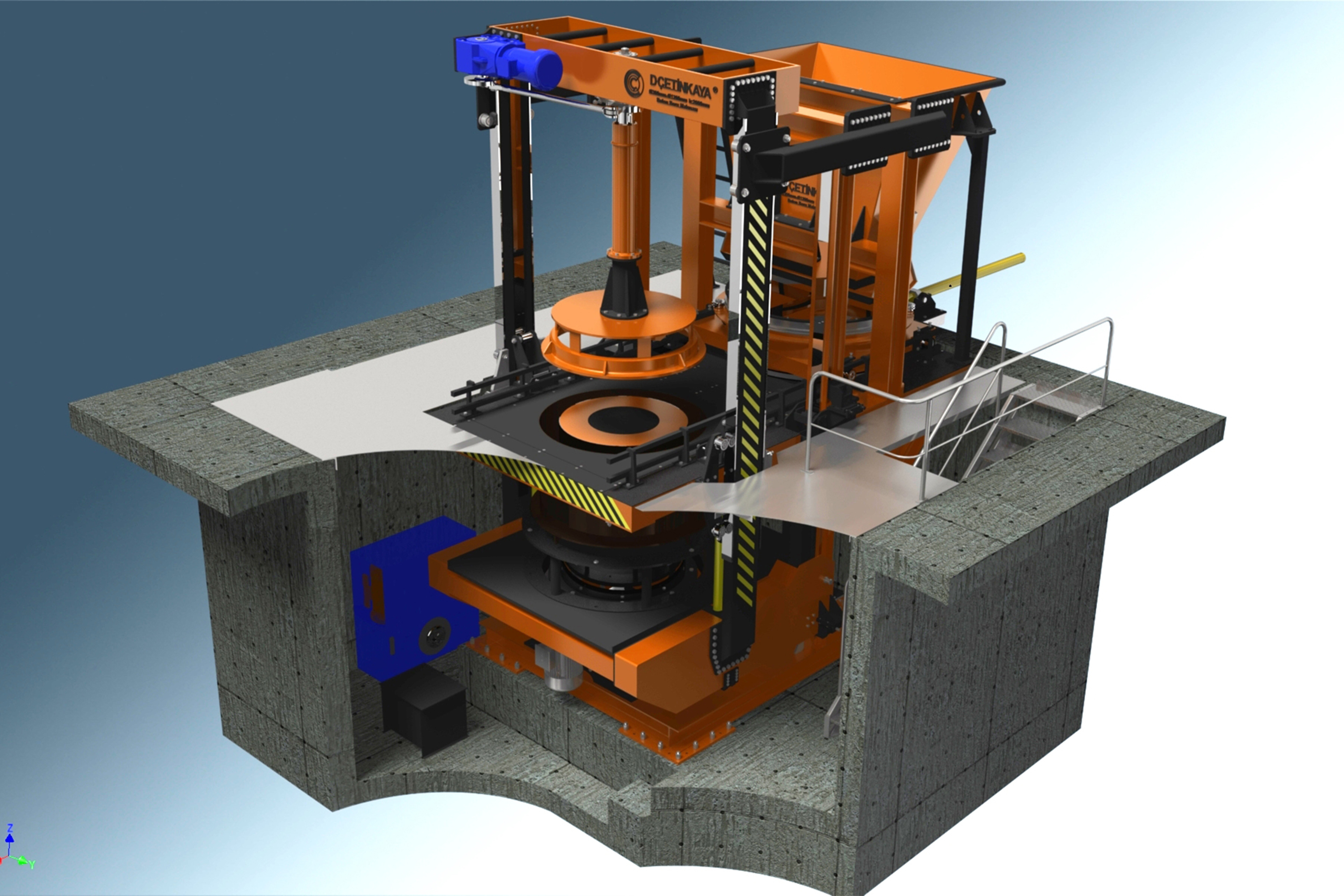

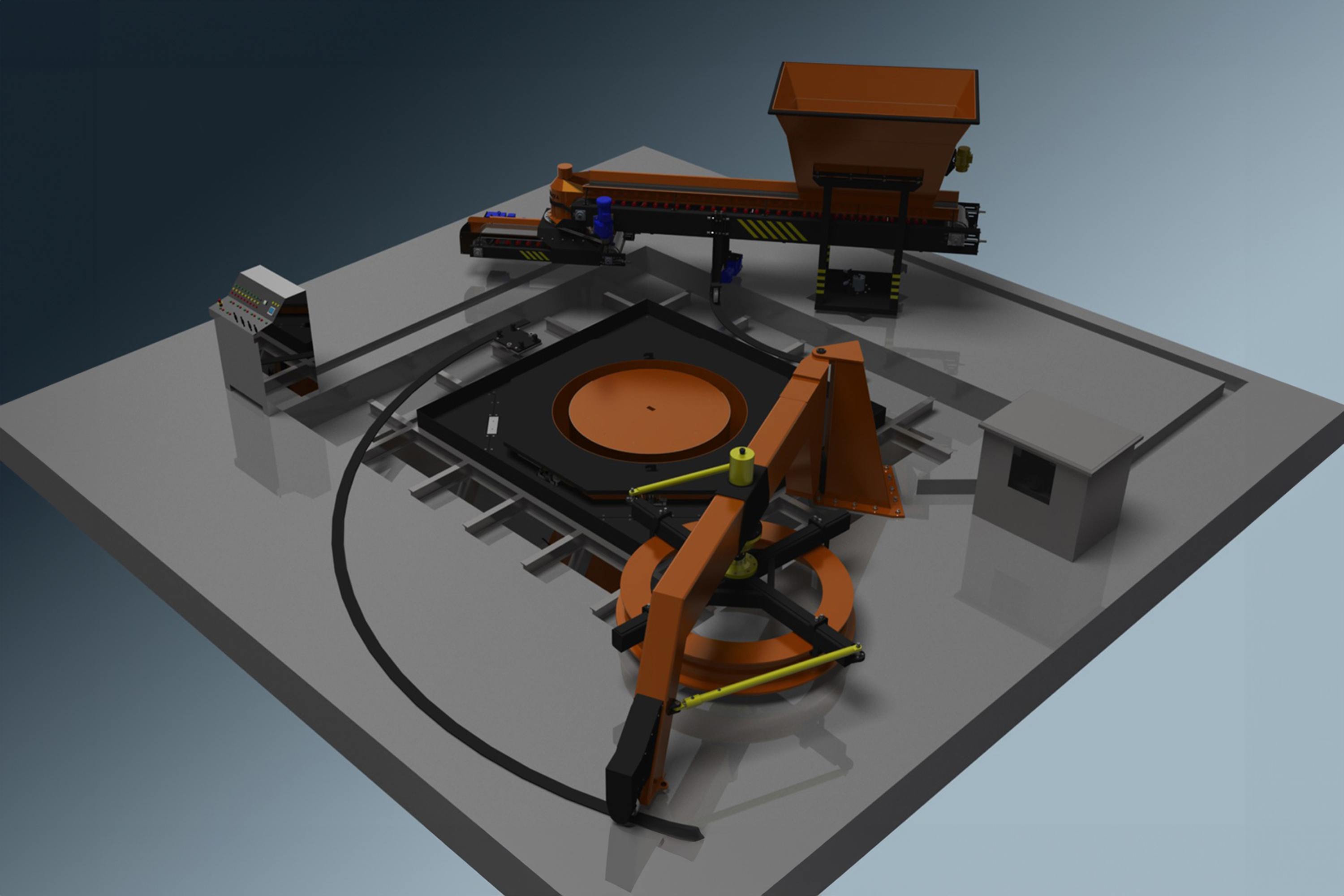

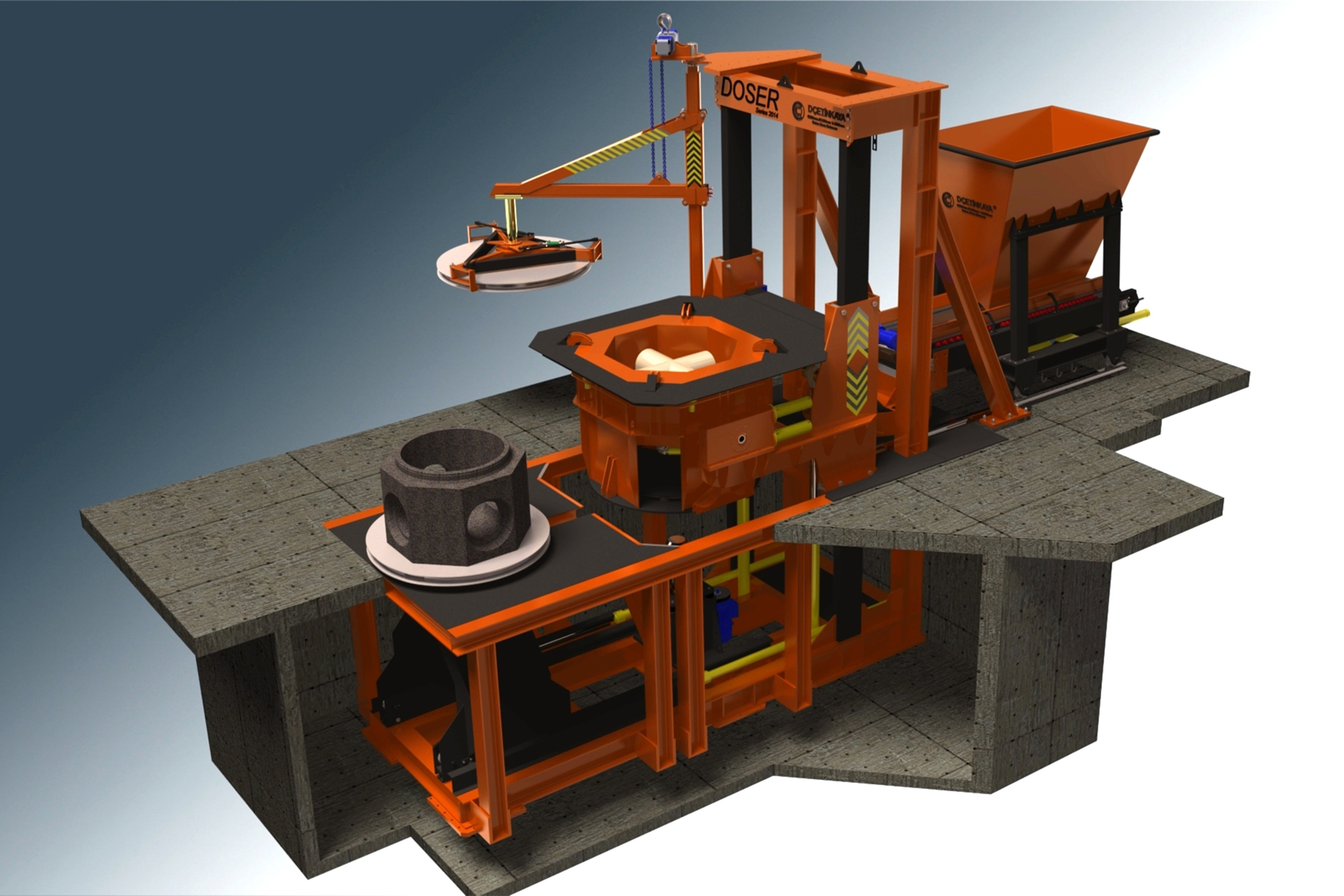

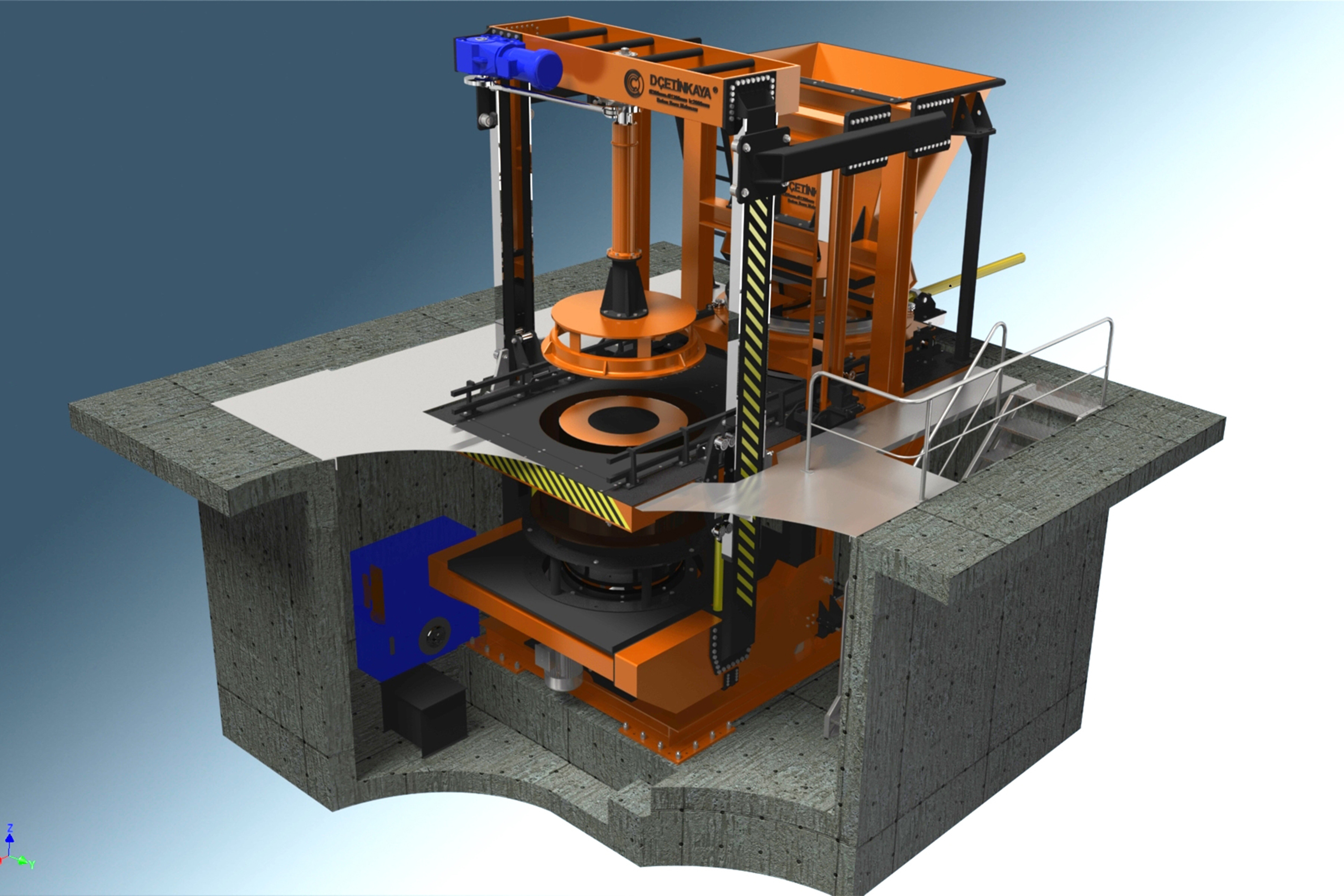

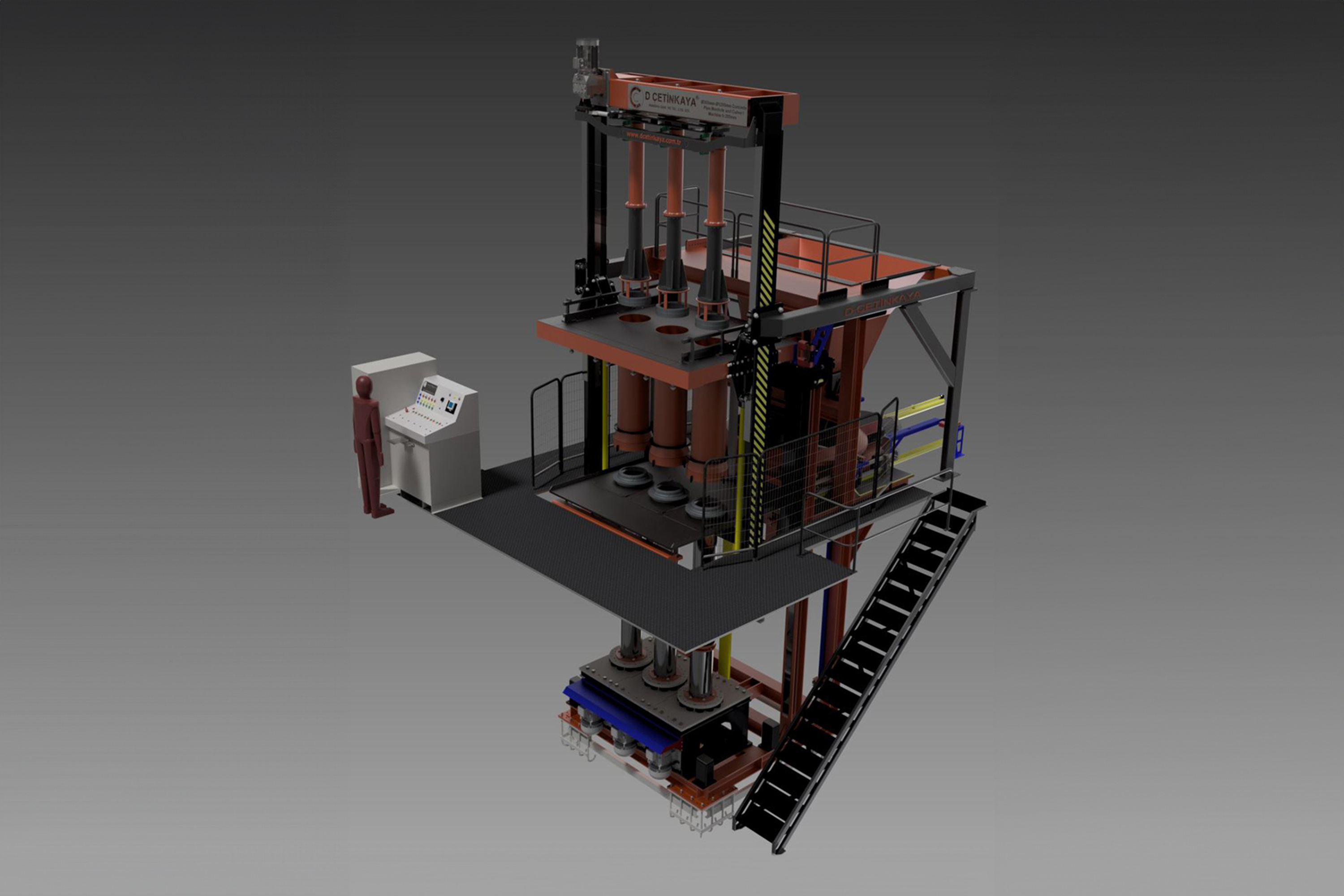

Construction (Main Frame): High-strength (ST 52) (ST 37) steel, with 0-level calibration on special benches, eliminating construction site level defects. CNC-processed upper plaster connection and lower vibrator groups. 25% heavier than similar machines, ensuring durability.

- Vibrator System: Liquid-oil closed circulation. Automatic lubrication activates with machine operation. Oil return is sensor-controlled, ensuring safety against user errors. Bearings are SKF or FAG. Vibrator power is steplessly adjustable from the control panel, saving time and labor.

- Hydraulic System: BOSCH-REXROTH (German) brand. All components tested at BOSCH-REXROTH’s test center. After assembly, the system is checked, adjusted, and prepared for shipment. Hydraulic units are positioned for noise, heat, and space reduction, with temperature and oil level sensors for continuous monitoring.

- Control Panel: Designed for easy operator use with SCHNEIDER (German) materials. Adjust hydraulic unit temperature, oil level, and vibrator power via the control panel, preventing job, worker, and time losses.

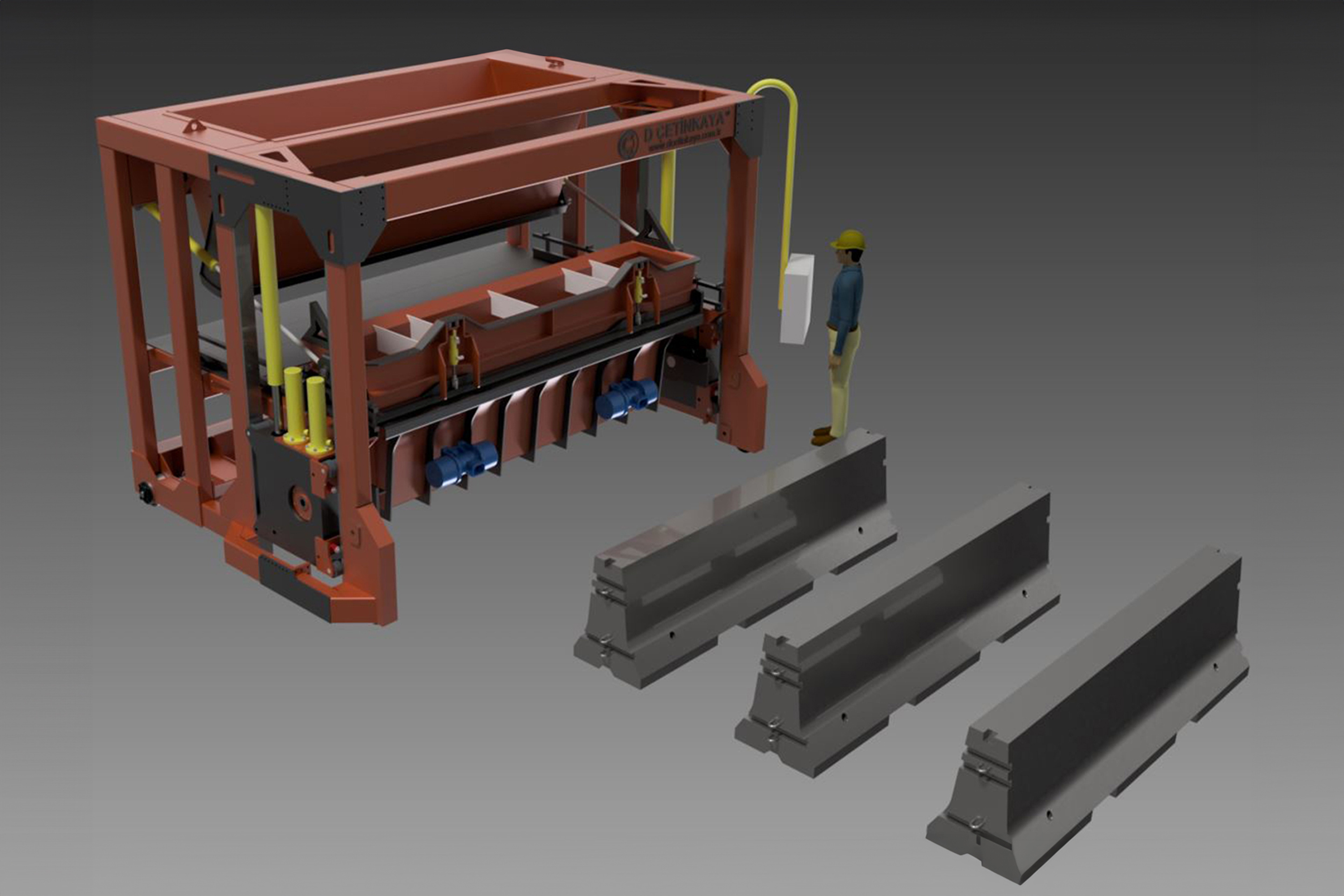

- Bunker and Mortar Distributor: 2 m³ mortar tank with chain gear protection cage for homogeneous mortar distribution.

- Safety and Sensors: Equipped with sensors and switches for job and worker safety, minimizing operator accidents. Steel guards protect moving parts. EMERGENCY STOP buttons are placed around the machine well and other points. Safe access and egress are provided with the machine ladder.

- Product Transport and Steaming: Products are transported to the steaming area by forklift. Transport baskets for the forklift are included. Forklift transport speeds up production.

- Molds and Pallets: Made from St52 steel, with mold clamping plates. Pallets comply with İller Bankası Standards and DIN 4032-4035 norms, CNC-machined, and packaged with protective wax to prevent rust until first use.